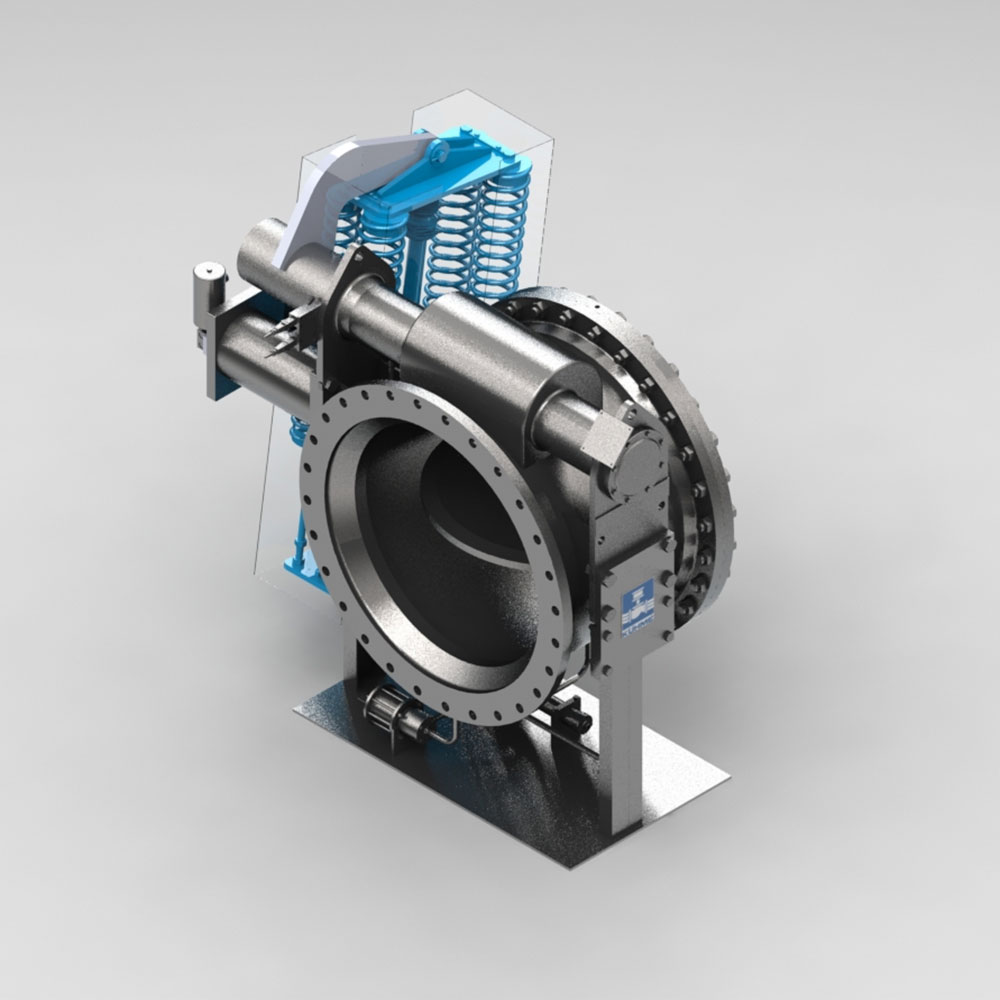

SAFETY QUICK-CLOSING

BUTTERFLY FLAP VALVE

TYPE PKIII/S

Safety quick-closing butterfly flap valves are an integral part of the containment. The butterfly flap valves are used in the ventilation system (HVAC) of the containment in nuclear plants. In case of an emergency, like “LOCA – Lost of cooling accident“ the butterfly flap valve shut-off quick and safe. The butterfly flap valve is also absolutely tight under earthquake conditions. The KÜHME safety quick closing butterfly flap valve is a benchmark for this application.

Nominal size:

DN 200 TO DN 1000

Operating pressure:

MAX. 7 BAR G

Operating temperature:

max. + 180°C

YOUR BENEFITS

- Reliable Closing time < 3 seconds

- Safety due to the proven tightness system meeting the tightness requirement of a leakage rate of 0.5 l/h at 20 mbar g

- Closing of the valve is dampened to reduce pressure surges in the pipeline

- Double seat – one valve instead of two separate valves – compact and cost-efficient solution

- Convenient automatic testing of the sealing system during plant operation – without having to dismantle the valve

- Heavy duty design for high amount of operating cycles

- High-performance valve with a long service life

OPERATION DETAILS

The quick-closing flap is operated by a pneumatic actuator with a solenoid valve. Automatic quick-closing relieves the pressure volume in the pneumatic actuator via the quick-exhaust valve. Closing springs laterally attached to the actuator close the flap. As the result of the lever kinematics the flap blade move in parallel – and thus nearly without any friction – into the sealing seat.