DYNAMIC MIXING AND CONTROL

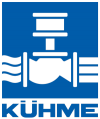

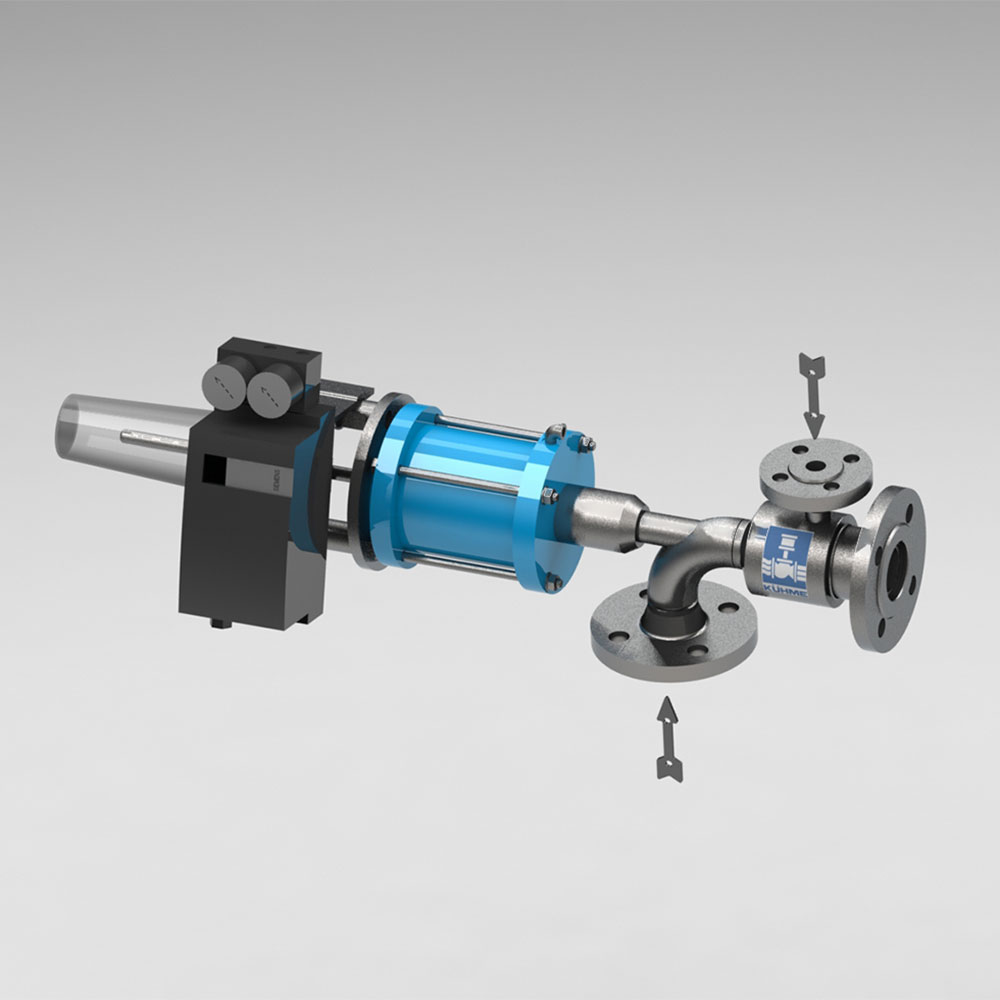

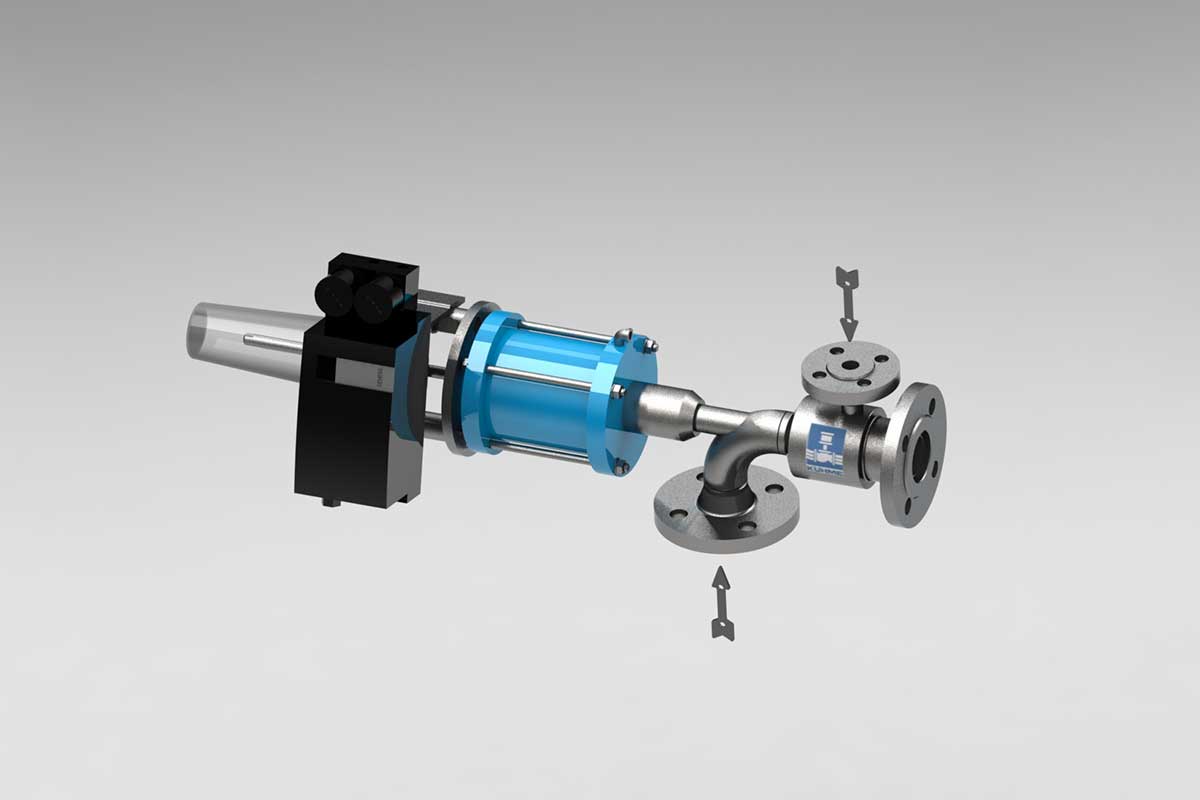

VALVE TYPE DGM

Fully automated control element for the flow control of gases. Exact mixing ratio as the second gas is fed in via the defined orifice cross section opening of the perforated basket element which may be adjusted by the stroke movement of the control device. Several mixing valves may be arranged in line for a multi-stage mixture of several gases.

Nominal size:

DN 25 TO DN 500

Operating pressure:

PN 6 – PN 25

Operating temperature:

max. + 200°C

YOUR BENEFITS

- Compact design

- Precise control of the gas injection for exact increase of the calorific value.

- Reliable media shut-off due to a robust plug sealing system

- For use in high process operating temperatures of up to 200°C

OPERATION DETAILS

The gases to be mixed (main and injection gas/es) are fed to the gas mixer. The dynamic gas mixer DGM controls the amount of the injection gas by means of the defined orifice cross section opening of the perforated basket element which may be adjusted by the stroke movement of the control device. This adjusts precisely the mixing ratio, allowing the optimum gas mixture over the entire control range. The closed-loop actuator is controlled via a positioner as demand requires.