KÜHME History at a glance

2020

• Upgrading of KÜHME Coating Facilities

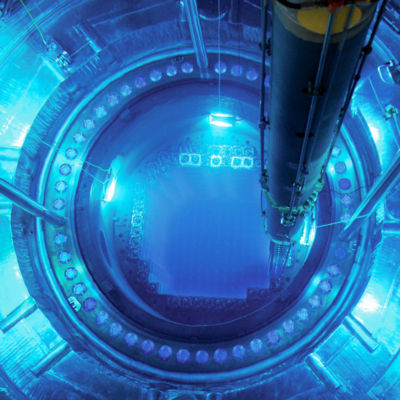

• Delivery of the large scale order for a nuclear power plant in Spain

• Webrelaunch - The new KÜHME website

• Delivery of the large scale order for a nuclear power plant in Spain

• Webrelaunch - The new KÜHME website

2019

• Delivery of the first 5 sets of GVU-NT's for a cruise ships

• Delivery of hybrid valve for the test bench of the Techinical University Berlin for control and safe shut-off of the exhaust gas flow at demanding + 649°C

• Next level and significant new development for a proven technology solution - new large scale order of Special Safety Cut-Off Dampers for Nuclear Power Plant in Spain

• Delivery of hybrid valve for the test bench of the Techinical University Berlin for control and safe shut-off of the exhaust gas flow at demanding + 649°C

• Next level and significant new development for a proven technology solution - new large scale order of Special Safety Cut-Off Dampers for Nuclear Power Plant in Spain

2018

• 2nd Edition of KÜHME's International Sales Conference was hosted near Frankfurt, Germany

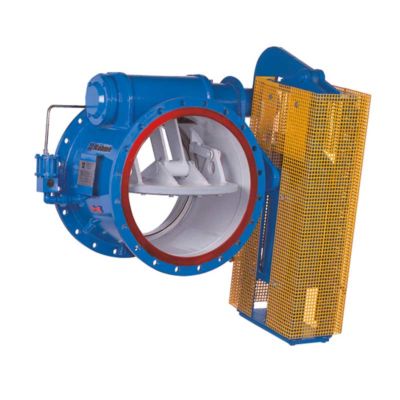

• Delivery of the first 16 sets of Butterfly Flap Valves for an air separation plant in Vietnam.

• First participation in the world's leading international trade fair for the maritime industry - SMM 2018 in Hamburg, Germany

• Delivery of the first 16 sets of Butterfly Flap Valves for an air separation plant in Vietnam.

• First participation in the world's leading international trade fair for the maritime industry - SMM 2018 in Hamburg, Germany

2017

• KÜHME celebrates 50th company anniversary with employees and their families

• Delivery of full package of valve stations for the Greek Power Plant Ptolemais

• Establishment of the subsidiary KUHME Valves India Pvt. Ltd

• Delivery of full package of valve stations for the Greek Power Plant Ptolemais

• Establishment of the subsidiary KUHME Valves India Pvt. Ltd

2016

• KÜHME's new Service Workshop inaugurated

• 1st Edition of KÜHME's International Sales Conference hosted at the Mining Museum in Bochum, Germany

• New development, testing and production of Gas Valve Units (GVU) for Marine applications

• Delivery of the first 12 sets of 3D-GVUs to MAN Diesel & Turbo SE for the World Biggest Crane Ship "SLEIPNIR"

• 1st Edition of KÜHME's International Sales Conference hosted at the Mining Museum in Bochum, Germany

• New development, testing and production of Gas Valve Units (GVU) for Marine applications

• Delivery of the first 12 sets of 3D-GVUs to MAN Diesel & Turbo SE for the World Biggest Crane Ship "SLEIPNIR"

2015

• Qualification, testing and certification of KÜHME valves for welding according DNV-GL

• KÜHME's Web Relaunch - Our new Webpage

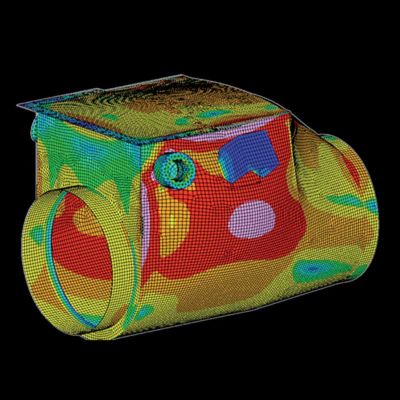

• New development of the KÜHME Gas Turbine Valves for higher pressures and higher temperatures with a closing time of ≤ 150 milliseconds

• KÜHME's Web Relaunch - Our new Webpage

• New development of the KÜHME Gas Turbine Valves for higher pressures and higher temperatures with a closing time of ≤ 150 milliseconds

2014

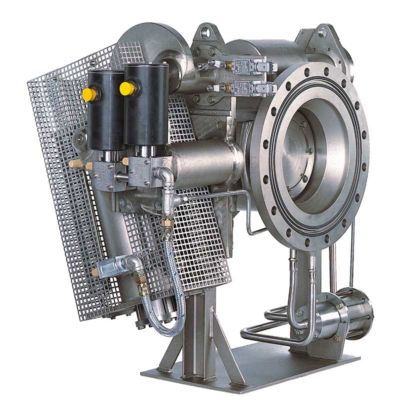

• KÜHME launches the new generation of electro-pneumatically actuated safety shut-off valves for Gas Tubines (ESD = Emergency Shut-Off Device) – closing time 0.1 seconds at DN 300

• Type examination certificated granted for self-medium controlled quick-closing valve type

• Audit successfully completed and certification granted for steel structures to be manufactured and executed in accordance to DIN EN 1090

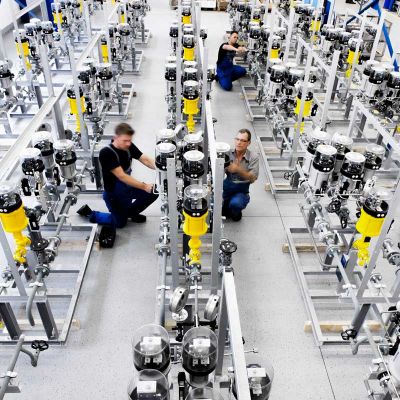

• Establishing the new KÜHME Supply Chain Center for bundling the entire workflow and improving process efficiency related to the internal production logistics

• Type examination certificated granted for self-medium controlled quick-closing valve type

• Audit successfully completed and certification granted for steel structures to be manufactured and executed in accordance to DIN EN 1090

• Establishing the new KÜHME Supply Chain Center for bundling the entire workflow and improving process efficiency related to the internal production logistics

2013

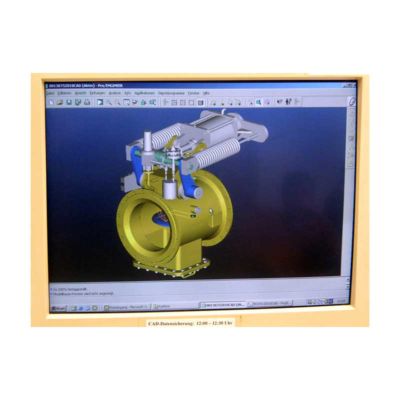

• Introduction of the new CAD System

2012

• KÜHME celebrates the company’s 45th anniversary with business partners, employees and their families

• Confirmation and certification of the KÜHME management system for safety, health and environmental protection in accordance with the most stringent SCC standard (Safety Certificate Contractors)

• Confirmation and certification of the KÜHME management system for safety, health and environmental protection in accordance with the most stringent SCC standard (Safety Certificate Contractors)

2011

• Delivery of the big scale order of containment tight cut-off damper technology (Safety Class 2) for the new modern Nuclear Power Plant Olkiluoto 3 in Finland, with a generation capacity of 1.600 MW and using the EPR™- Technology

2010

• Restructuring and reorganization of the entire production work-flow. Installation of dedicated product-focused assembly centers including introduction of KANBAN as a new modern supply approach for parts and components

• Development and supply of a new selective Gas Injection Device for Steel Plant Bremen – Gas Injection Device DN 400 and 3.500 mm long. Application: Gas injection into Steel Converter Gas line

• Development and supply of a new selective Gas Injection Device for Steel Plant Bremen – Gas Injection Device DN 400 and 3.500 mm long. Application: Gas injection into Steel Converter Gas line

2009

• Completion and delivery of large scale order volume of quick-closing valves for Gas Compressors as well as automatic two-dimensional mixing valves for installations at Biogas Plants

• AREVA awards KÜHME the Top Supplier Award.

• AREVA awards KÜHME the Top Supplier Award.

2008

• Signing of a frame contract about an extensive and remarkable supply volume of advanced KÜHME quick closing technology to be part of the sustainable modernization and new build program for new Power Plants in Germany, Europe and South Africa

• 520 Pulverized coal dust dampers

• 850 Customized valve stations for a safe fuel management compact & integrated design, workshop assembled and tested, ready to be directly connected and operated

• 520 Pulverized coal dust dampers

• 850 Customized valve stations for a safe fuel management compact & integrated design, workshop assembled and tested, ready to be directly connected and operated

2007

• The first electro-pneumatically safety shut-off valves for the process fluids methane and methanol used in the petrochemical sector are developed and installed. Cryogenic operating temperatures of down to minus 165° C

• Commissioning of a new, modern and CNC-controlled machining centre with 5 axes, with an integrated, fully automated tool magazine and 60 tools

• Kühme valves are qualified and certified in acc. with SIL 3 - IEC 61508

• Commissioning of a new, modern and CNC-controlled machining centre with 5 axes, with an integrated, fully automated tool magazine and 60 tools

• Kühme valves are qualified and certified in acc. with SIL 3 - IEC 61508

2005

• Inauguration of the newly built KÜHME Training Center equipped with modern multimedia technology

2004

• Delivery of fully tested valves stations designed as complete systems for safe fuel gas shut-off upstream of Gas.

2003

• Acquisition and integration of the product line ”Single-Plate Gate Valves – PSA-DELI and ELI series” of P+S Armaturen GmbH, Zweibrücken – Germany.

2002

• Delivery of a large scale order of KÜHME quick-closing dampers for installation at an Air Separation Plant. Application specifics: Alternating pressure and plant operated to generate O2 and N2

2001

• Certification of the Kühme QA system in acc. with the European pressure equipment directive.

1998

• Company premises enlarged by 1,600 qm and new production hall built with increased crane carrying capacities of 10 t. Modernisation and further automation of the welding production processes

1997

• Introduction of the new 3D CAD system for the entire KÜHME design team.

1994

• Capital increase and change of the company name into KÜHME Armaturen GmbH

• Certification of the Kühme QA system in acc. with DIN EN ISO 9001

• KÜHME develops and delivers new quick-closing safety valves with integrated double sealing system for coke oven gas, a very critical and demanding fuel gas in steelworks. Meanwhile, this KÜHME valve series has also been type-tested.

• Certification of the Kühme QA system in acc. with DIN EN ISO 9001

• KÜHME develops and delivers new quick-closing safety valves with integrated double sealing system for coke oven gas, a very critical and demanding fuel gas in steelworks. Meanwhile, this KÜHME valve series has also been type-tested.

1990

• Extension and further storeys added to a new and modern office building

1989

• Certification of the KÜHME quality assurance system for nuclear plants in acc. with the KTA 1401 regulations.

1987

• New development, testing and production of safety shut-off dampers for pulverized coal being used as fuel in Power Plants

1985

• Dimensioning, design and production of the first integrated valve stations – KÜHME establishes itself as a system provider. Today, at KÜHME, more than 200 valve stations are designed and produced individually according to the customer’s requirements per year.

1984

• Expansion of the company premises by 3,600 qm with an additional production hall and increased double crane arrangement of 5 tones capacity each.

• Development, production and delivery of fuelling valves for airports – process medium: Kerosene. Nato approval issued.

• Development, production and delivery of fuelling valves for airports – process medium: Kerosene. Nato approval issued.

1982

• New development, testing and successful marketing of the two-dimensional mixing valve.

1980

• The company is enlarged by a new production hall of 1,000 qm and extended office buildings.

1978

• Kühme develops and installs special quick-closing and control valves for operation at PSA plants for hydrogen generation. Maintenance-free valves for 160,000 switching cycles and load changes.

1974

• Development, production and testing of the first tight cut-off dampers (Safety Class 2) to be installed in Nuclear Power Plants.

• Implementation of a comprehensive and recognised quality assurance system - corresponds to the current DIN ISO 9001.

• Implementation of a comprehensive and recognised quality assurance system - corresponds to the current DIN ISO 9001.

1971

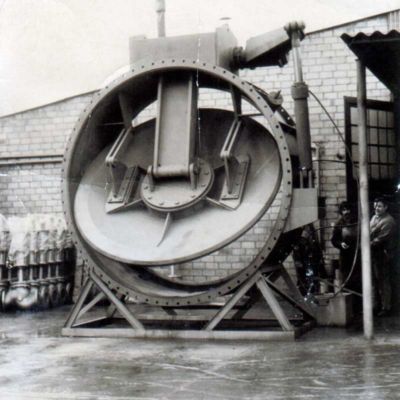

• The first quick closing damper of up to DN 3000 mm nominal size for a safe shut-off of blast furnace gas in Steel Plants are developed, produced and delivered by KÜHME

1969

• The young company relocates from Duisburg to Bochum.

New production hall and office building – Am Vorort 14 in Bochum.

New production hall and office building – Am Vorort 14 in Bochum.

1967

• Establishment of the private company Ernst KÜHME KG Spezialarmaturen in Duisburg, focussing in safety shut-off valves, gas-air failure devices, gas pressure regulators, vapour pressure regulators and pneumatic piston and diaphragm valves