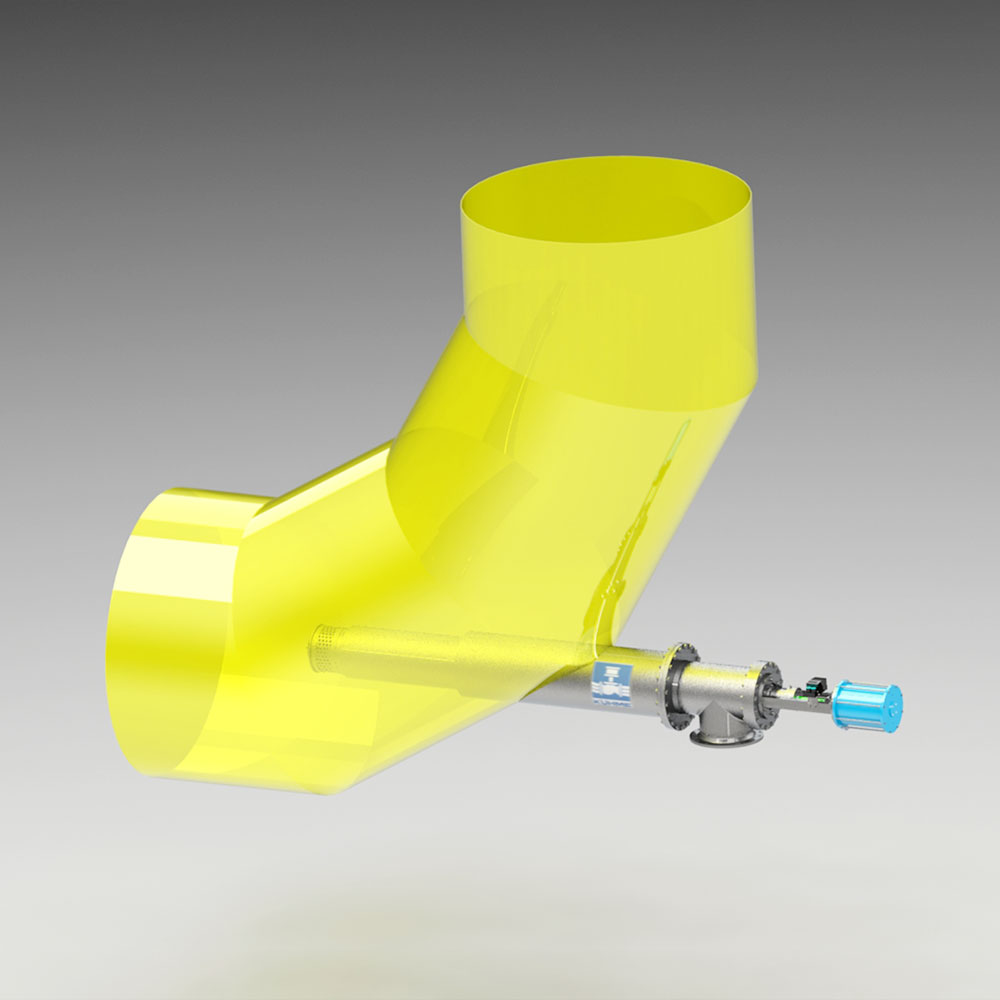

INJECTION GAS MIXING

VALVE TYPE IGM

The injection gas mixing valve type IGM is integrated into the main pipelines of gas mixing plants to selectively increase the calorific value or to stabilise the calorific value of big gas volumes.

Nominal size:

DN 50 TO DN 500

Operating pressure:

PN 6 – PN 16

Operating temperature:

max. + 300°C

YOUR BENEFITS

- Precise control of the gas injection for selective increase of the calorific value.

- Reliable injection media shut-off due to robust plug sealing system

- Suitable for high operating temperatures up to 300°C

OPERATION DETAILS

Purpose of the IGM-Device is to selectively inject upgrade-gas into a main gas flow. The IGM-Device controls the amount of gas to be injected by means of exactly opening the required orifice cross section as part of the perforated basket on tip of the injection lance. During the injection operation the gas is leaving the perforated basket in an exactly controlled radial flow pattern. This radial injection flow pattern ensures quick and very homogenous overall mixing behavior, which is essential for reliable operation of the plant respectively the downstream combustion process.